By Lt Col Narendra Tripathi (r)

The Dawn of a New Warfighting Paradigm

As drone warfare increasingly shapes the nature of modern combat, the Defence forces are reportedly considering the formation of dedicated drone platoons at the unit level. While still unconfirmed, this initiative aligns with global military trends and reflects a deeper understanding of the transformative potential of unmanned aerial systems. Ukraine’s use of FPV and kamikaze drones in Operation Web Spider has demonstrated how low-cost, fast-deploying drones can deliver outsized effects on high-value enemy targets. These platforms offer unique advantages in terms of agility, scalability, and cost efficiency, often surpassing conventional systems in dynamic combat environments.

Yet, this enthusiasm has sparked a troubling countertrend: improvised manufacturing using 3D-printed frames, underpowered motors, and untested subsystems. Although such DIY approaches may offer tactical utility in specific scenarios, they lack the standardisation and dependability required for sustained combat operations. The risks are particularly high with loitering munitions or autonomous strike drones, where a lack of secure identification protocols can lead to fratricide.

To harness drones effectively, India must move beyond ad hoc solutions and focus on building a self-reliant drone ecosystem. This includes indigenous hardware, secure software, robust support systems, and integration with established military doctrine, ensuring that FPV and multirotor drones become dependable and scalable assets in future warfare.

Understanding FPV and Multirotor Drone Capabilities

Before developing a strategy, it is essential to understand the capabilities of FPV (First-Person View) and multirotor drones, which are pivotal in modern drone warfare. FPV drones are manually flown using real-time video feeds streamed to headsets or monitors, enabling high-speed, precise strikes and agile movements in confined environments. Their effectiveness has been demonstrated in contested zones where conventional systems may be too costly or slow to deploy.

Custom FPV designed with Day/Night capability. Pic Courtesy: www.zenerativeminds.com

Multirotor drones offer vertical take-off and landing (VTOL), hover, and loitering capabilities, ideal for India’s operational terrains, including high-altitude regions near the LoC and LAC or urban CI/CT zones. Their compact form and excellent manoeuvrability allow operations in GPS-denied or jammed areas.

Indigenous VTOL-based Loiter Munitions. Pic Courtesy: https://scientechworld.com/

These drones are also modular and cost-effective, capable of carrying various payloads such as cameras, munitions, or jammers, enabling them to switch roles between surveillance, strike, and electronic warfare. Together, FPV and multirotor drones provide a combination of agility, affordability, and adaptability, making them essential to the Indian Army’s evolving tactical doctrine and future force structure.

Challenges and Pain Points

Although any modern force would aspire to achieve technological superiority using FPV and multirotor drones on the battlefield, several critical challenges must be addressed before these systems can be deployed at scale with confidence.

One of the foremost issues is the lack of standardisation across drone platforms. In many cases, units rely on ad hoc designs that vary widely in quality, performance, and reliability. This inconsistency not only hampers interoperability but also complicates maintenance and logistics. Drones made locally in-house incorporate 3D-printed frames and commercial off-the-shelf (COTS) components. These materials may be sufficient for training or testing, but fall short in withstanding the rigours of battlefield conditions. Their limited durability makes them unreliable in high-temperature zones, wet terrain, or sustained operations.

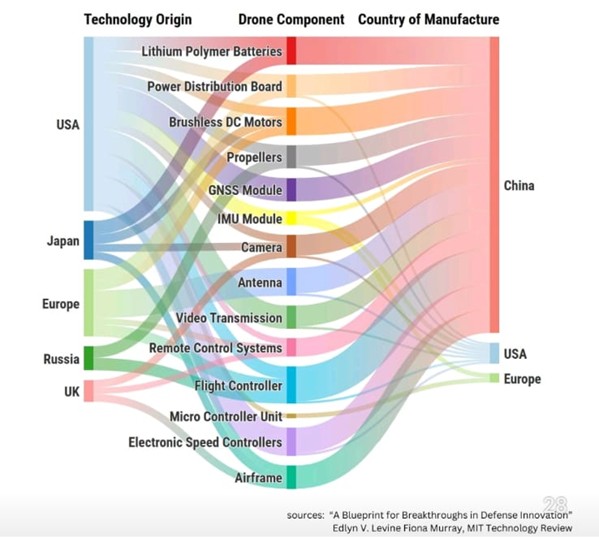

Another primary concern is the fragility of the supply chain. A significant portion of critical components, such as brushless motors, flight controllers, and radio modules, are imported, often from non-trusted sources. This dependence introduces strategic vulnerabilities, especially during wartime when sanctions, export bans, or logistic disruptions may cut off access to essential parts.

Equally pressing is the issue of training. Currently, there is a gap in a defence-based, structured, pan-India training pipeline for drone operators, maintainers, and mission planners. Without standardised curricula and simulator-based instruction, the force risks inconsistent handling and suboptimal deployment of these valuable assets.

Electronic warfare (EW) also poses a serious challenge. Many FPV drones, especially those adapted from hobbyist models, are easily jammed or spoofed using readily available RF disruption equipment. This makes them unreliable in contested environments where adversaries actively deploy EW systems. Additionally, data security is a growing concern. Drones with unsecured communication links are prone to interception, hijacking, or data leaks, potentially compromising sensitive operational intelligence.

Should the Forces Manufacture Drones In-house?

The concept of in-house or localised drone manufacturing, particularly through 3D printing and commercial off-the-shelf (COTS) components, has gained attention for its low cost and rapid prototyping potential. In fast-moving operational environments, such decentralised approaches may seem agile and responsive. However, while appealing in the short term, this model presents critical long-term challenges that can compromise operational success.

One of the foremost concerns is reliability. Drones built at the unit level often rely on untested parts and improvised assembly, bypassing established protocols for quality assurance, environmental hardening, and flight validation. In demanding conditions, such as high-altitude or contested zones, this lack of standardisation can lead to catastrophic technical failures.

Moreover, expertise in drone design, calibration, and parameterisation is limited. Building a drone is not merely assembling parts; it involves precise aerodynamic tuning, controller calibration, payload balancing, and extensive flight testing, elements typically requiring specialised R&D teams. Without this, even well-intentioned efforts result in underperforming platforms.

Training gaps also widen the risk. Personnel often lack formal instruction in drone engineering, resulting in inconsistent builds and unsafe operation practices. Over time, this leads to inefficiencies, mission failures, and accidents.

The issue of interoperability further complicates matters. Divergent configurations across units, varying motors, flight controllers, software, and communication protocols, disrupt joint operations and make scaling, integration and sustainment across formations difficult.

From a logistical and financial standpoint, managing multiple non-standard platforms creates strain. Spare parts, repair protocols, charging systems, and training efforts multiply unnecessarily. Most importantly, drones built without robust engineering foundations often fail to endure till the mission’s end, resulting in wasted resources and sunk costs over time.

Drone Technology Vs Country of Manufacture. Pic Courtesy: Edlyn V Levine, Fiona Murray, MIT Technology Review

Way ahead: Building a Self-Reliant Drone Ecosystem

To fully harness the tactical and strategic capabilities of these drones, the Defence forces must shift from ad hoc experimentation to a structured, sustainable, and long-term drone integration strategy. This effort must extend beyond procurement to encompass end-to-end development, from indigenous hardware and secure software to operator training, maintenance infrastructure, and battlefield deployment. At the heart of this transformation lies the proven Six Pillars of Sustainment, a doctrine followed by the Corps of Electronics and Mechanical Engineers (EME), which provides a robust framework for operational readiness and lifecycle management.

Training the Trainers for Drone nuances. Pic Courtesy: www.zenerativeminds.com

The first pillar, Skilled Manpower, remains foundational. Officers & Soldiers must now be trained not just in traditional maintenance but also in drone-specific diagnostics, AI-enabled fault prediction, and cyber-physical systems. Supporting them is the second pillar: Specialised Tools and Test Equipment. This includes drone-calibrated test benches, environment-specific diagnostic kits, and AI-integrated systems to ensure precise and predictive fault identification.

Essential Infrastructure, the third pillar, must extend from static workshops to mobile units that include drone bays, EO test labs, and 3D printing capabilities (excluding frame printing). These facilities should be capable of supporting drones in forward deployments, ensuring mission continuity. The fourth pillar, Timely Repairs and Maintenance, now requires a drone-centric PMS (Preventive Maintenance Schedule), real-time diagnostics, and integration with digital platforms like the Workshop Automation Software Program (WASP) to ensure seamless workflow management.

Spares management plays a vital role in ensuring drone fleet readiness, primarily through the standardisation of key components such as motors, batteries, and flight controllers. Implementing predictive stocking strategies and collaborating with indigenous startups can significantly minimise downtime and enhance operational availability. The sixth pillar, Major Overhauls and Interventions, should encompass structured mid-life upgrades, airframe retrofits, firmware updates, and periodic recertification, executed through joint efforts between OEMs and in-house maintenance teams. However, for smaller drones, maintaining readily available “Zip kits” containing essential replacement parts may offer a more efficient solution to address obsolescence and maintain long-term serviceability.

Central to all this is indigenisation. Continued reliance on imported flight controllers, GPS modules, and communication hardware not only raises logistical challenges but also increases strategic vulnerabilities. There is a need to equip in-house R&D institutions (SDD), Defence academia (CME, MCEME, MCTE) and defence production agencies (Army Base Workshops) for having deeper collaborations between DRDO, DPSUs, premier institutions like IITs, and emerging startups to develop rugged, upgradable drones that can perform across terrains.

Seminars and Panel discussions on Drone tech at the Ikon Young Entrepreneurs and Business Leaders Summit in Hyderabad

Equally vital is the development of secure software stacks. Off-the-shelf firmware, while useful in commercial applications, falls short of military needs. India must invest in tamper-proof flight control systems, encrypted telemetry, and AI-based software that supports autonomous navigation, swarm logic, threat detection, and anti-jamming communication protocols. Developing this software infrastructure must be a national effort, led by IITs and IIITs and supported by defence R&D labs.

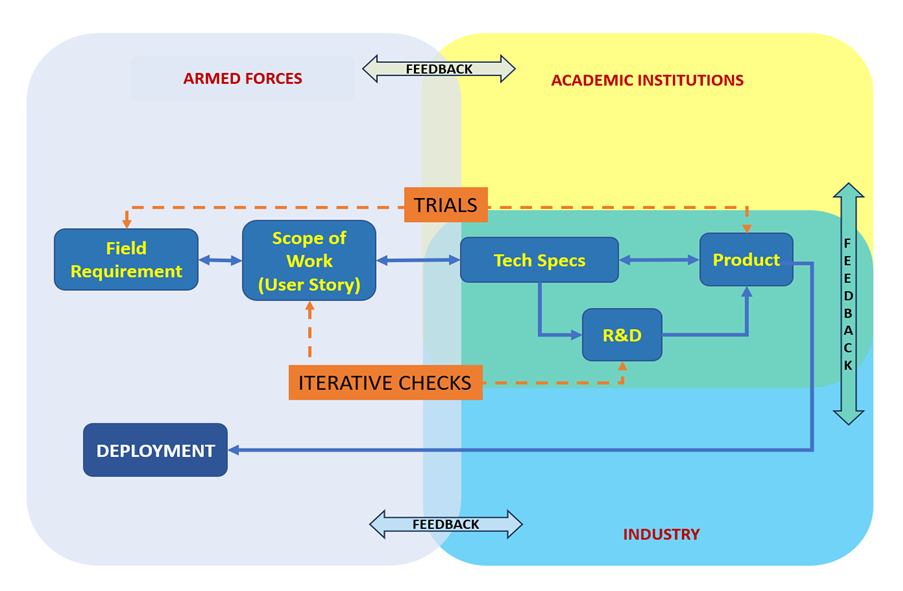

To sustain this innovation, academic–industry–military collaboration must be institutionalised. Training academies should evolve as feeders of drone talent, producing trained pilots, engineers, and maintainers. Meanwhile, startups can provide nimble prototyping and rapid iteration, allowing for real-world feedback to refine systems quickly.

Designing solutions using the Triple Helix Model, conceptualised by Lt Col Narendra Tripathi

Lifecycle support must not be an afterthought. Every drone-operating unit should be backed by forward repair teams, spare provisioning hubs, battery recycling systems, and telemetry health tracking. Static and mobile workshops should ensure minimal downtime, while AR/VR simulators can prepare drone pilots for high-stress FPV missions and synthetic training scenarios.

While recent trends in unit-level drone manufacturing using 3D printing and COTS components offer tactical agility, this decentralised model risks long-term mission sustainability. Lack of environmental testing, quality assurance, and cybersecurity makes such drones unsuitable for serious combat applications. The Army should instead focus on custom payload integration and mission-specific adaptation at the unit level, while keeping airframe production and core systems under standardised, centrally managed defence production.

By grounding its drone capability in structured doctrine, the Six Pillars of Sustainment, and a collaborative national ecosystem, the Defence forces can evolve from a consumer of unmanned systems to a global leader in battlefield drone innovation. This approach ensures scale, resilience, and readiness across future multi-domain operations.

Unique R&D efforts for miniature Nano FPV Drones. Pic Courtesy: Daksh

Sustainment and Training: The Backbone of a Scalable Drone Ecosystem

For drones to truly function as force multipliers in the Indian Army, their sustainment must be prioritised with the same rigour as their deployment. Operational effectiveness hinges not only on the availability of drones but on their ability to endure, recover, and perform reliably, especially in remote or contested environments.

A robust sustainment framework involves logistics, technology, and skilled manpower. Critical to this is a secure, indigenous supply of Lithium-Ion or Li-Polymer batteries. Alongside, essential components like brushless motors, ESCs, propellers, and sensors must be stocked at key logistic nodes. Forward-deployed mobile repair units with diagnostic kits, battery conditioners, and 3D printers can significantly reduce downtime.

AI-driven predictive maintenance systems should be integrated to monitor wear and battery health, reducing mission risk. Drones must also be built with electronic warfare resilience, featuring anti-jamming capabilities, secure multi-band communication, AI fallback controls, and fail-safe functions such as return-to-base. Doctrine must define when assets, exceptionally cost-effective FPV drones, are to be repaired, upgraded, or decommissioned. Repair hubs at brigade or corps levels can ease the burden on frontline units.

Lt Col Narendra Tripathi (r) is an alumnus of IIT Kanpur with research in Exoskeleton. He is also an SME and independent consultant in military technology.